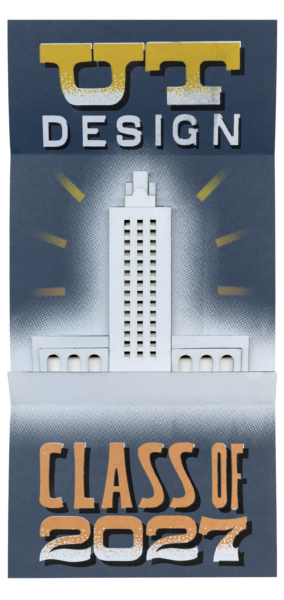

Design Lab

Home of the RRK, and the home base for UT Design

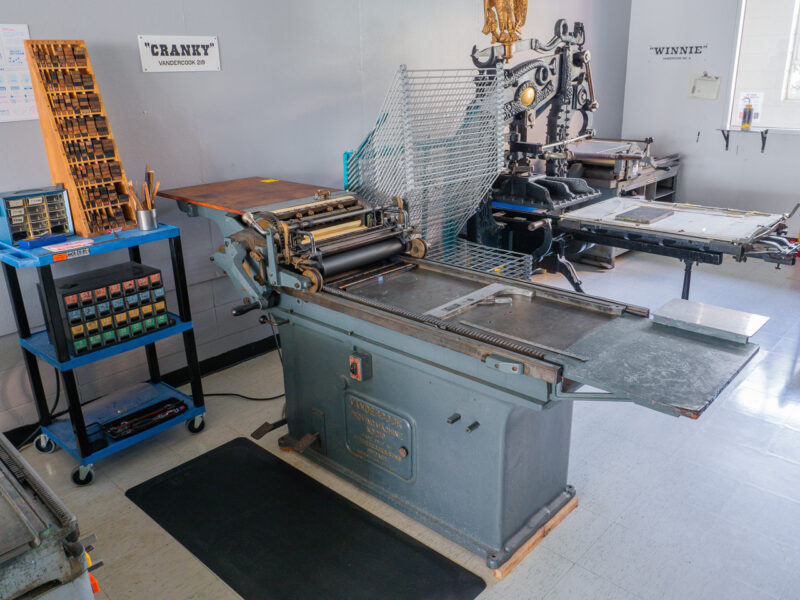

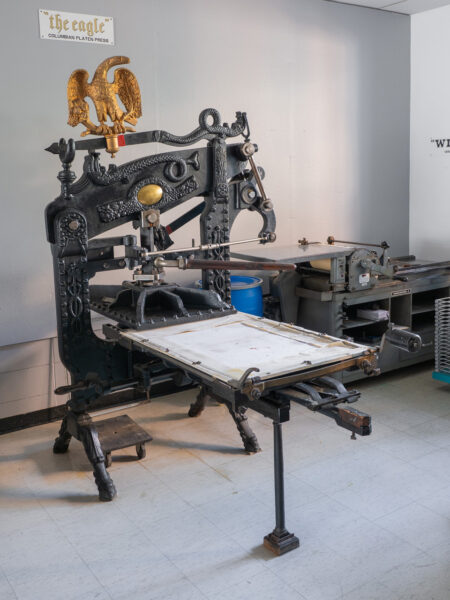

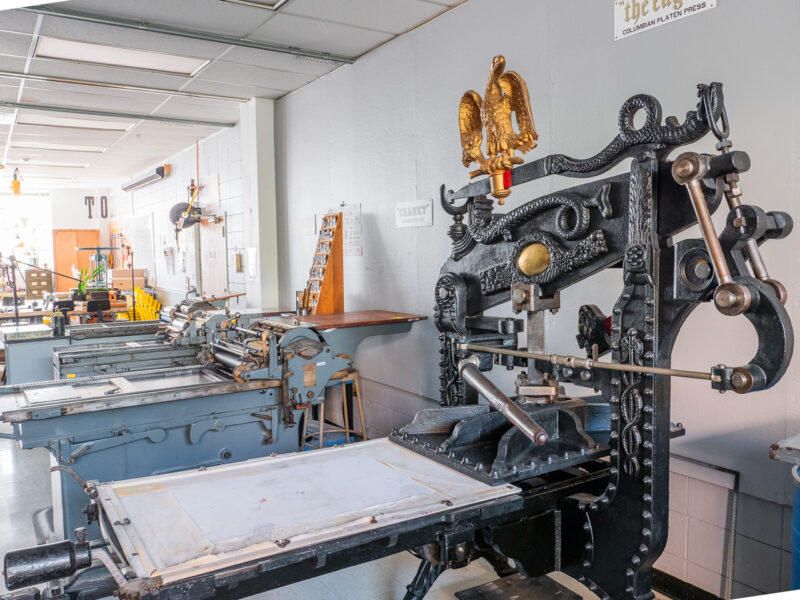

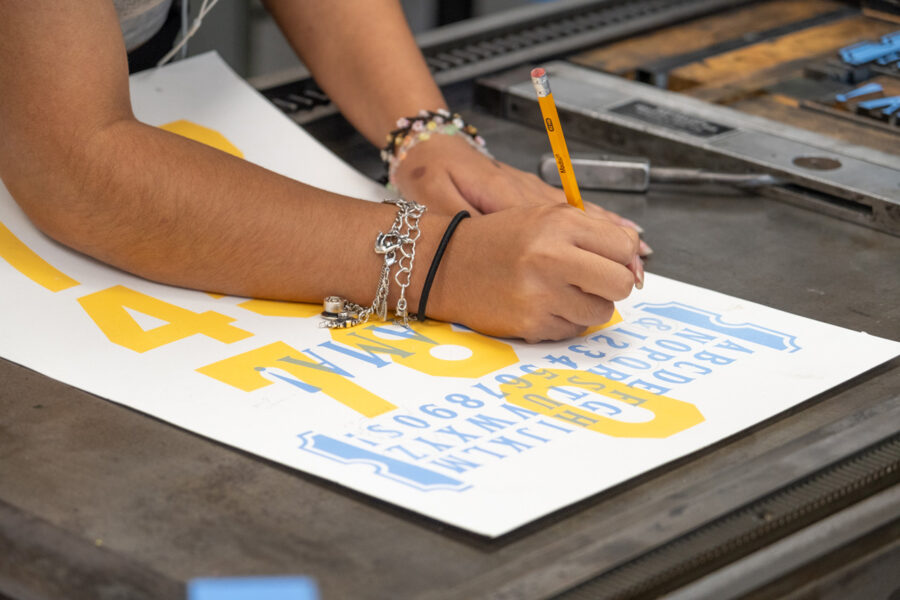

The UT Design Lab—part of the School of Design & Creative Technologies—is a mixed-use fabrication space, with a primary focus on printmaking. The lab houses the Rob Roy Kelly American Wood Type Collection (the RRK), as well as a variety of antique printing presses, screen printing facilities, and various resources for 2D and 3D making. As a focal point of SDCT, the lab is a community space, in addition to being an energizing and accessible workspace with a vast assortment of tools and materials.

The lab offers a wide range of resources outside of printmaking, such as sewing facilities, photography equipment, digital scanning and printing, woodworking tools, and other resources for 3D fabrication. Trained students and faculty can access the space 24/7, though some resources are closed after staff hours.

For further information and inquiries, please contact Henry Smith, the Design Lab manager and custodian of the RRK, at henry.smith@austin.utexas.edu

Presses & Equipment

Letterpress & Relief Printing

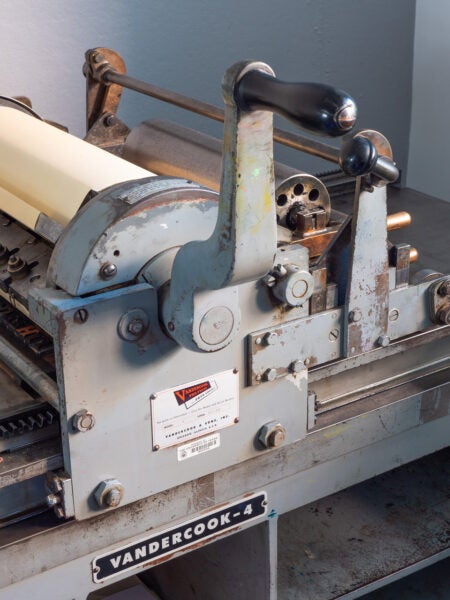

- Vandercook No. 4 Proofing Press (two)

- Vandercook SP15

- Vandercook SP20

- Vandercook No. 219

- Columbian Platen Handpress

- 8×10 C&P New Style Platen Press

- 5×8 Kelsey Excelsior Platen Press (tabletop)

- Kwikprint Model 55 Hot Foil Stamper

- Photopolymer Plate Maker

Screen Printing

- Vastex 4-color Garment Printing Press

- Vastex 1-color Garment Printing Press

- Cincinnati Screen Printing Vacuum table

- Screen Exposure Unit & Washout Facilities

Cutting, Binding, & Sewing

- Q. Vaggeli 40” Board Shear

- Challenge 26” Paper Guillotine

- Sailrite Industrial Sewing Machine

- Brother Serger

- Tamerica Omega-4in1 Spiral Binder

- Roland 24” Vinyl Cutter

- Cricut Maker 3

The Student Residency Program

Since the summer of 2021, the Design Lab has hosted a student residency program for undergraduate Design students. This program provides students with paid opportunities to connect with professional projects, and to delve into explorations of the RRK collection and other printmaking resources.

The program thus far has primarily focused on an endeavor to print a new folio of the entire RRK collection, a project that began in the summer of 2022, and is ongoing indefinitely.

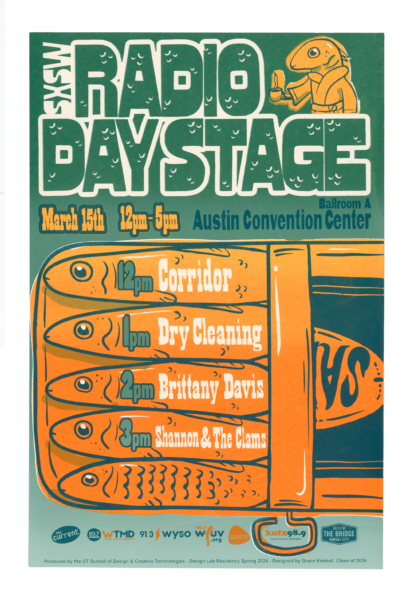

Throughout the school year, students also participate in semester-long opportunities to work with clients on UT campus. We continue ongoing work with the School of Design & Creative Technologies, alumni association Texas Exes, and local Austin NPR music station KUTX 98.9.

A main goal of this project has been to share the RRK collection with our community. Austin has an acclaimed history of live music posters and printmaking. Our hope is to participate in this continued legacy, by inspiring and enabling our students to embrace the power of the collection.